PUMPS FOR SANITARY AND INDUSTRIAL APPLICATIONS.

UNIVERSAL INTELLIGENT DESIGN FOR EVERY APPLICATION

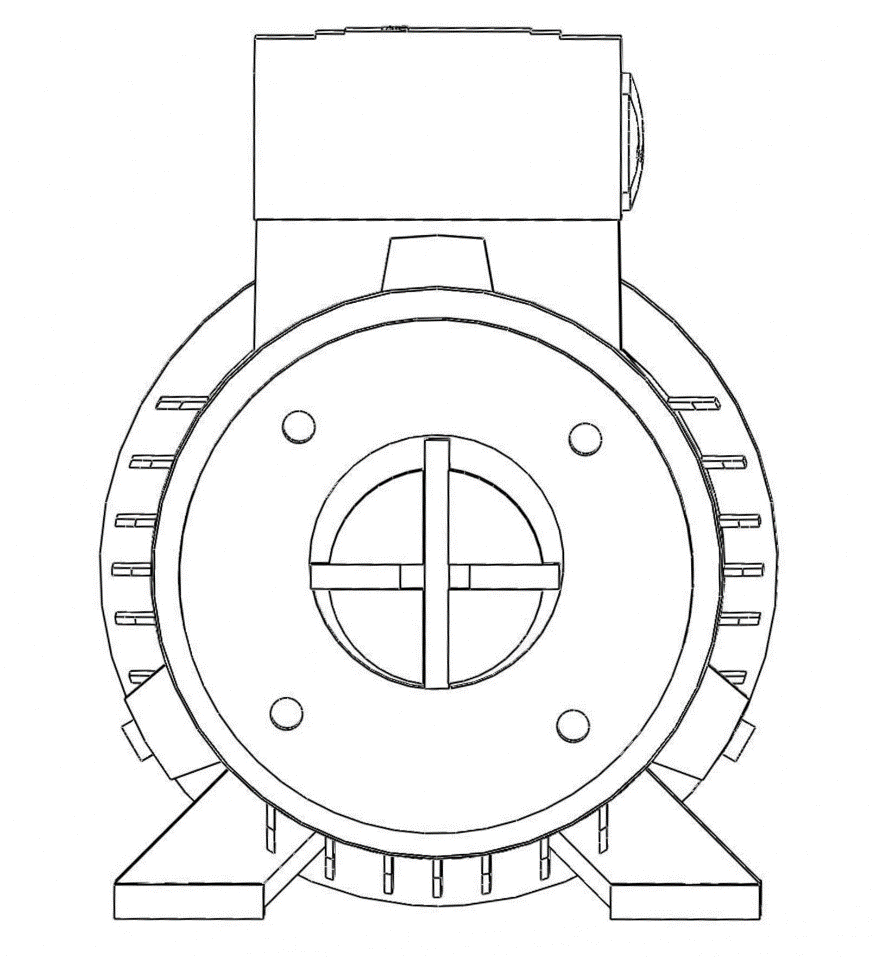

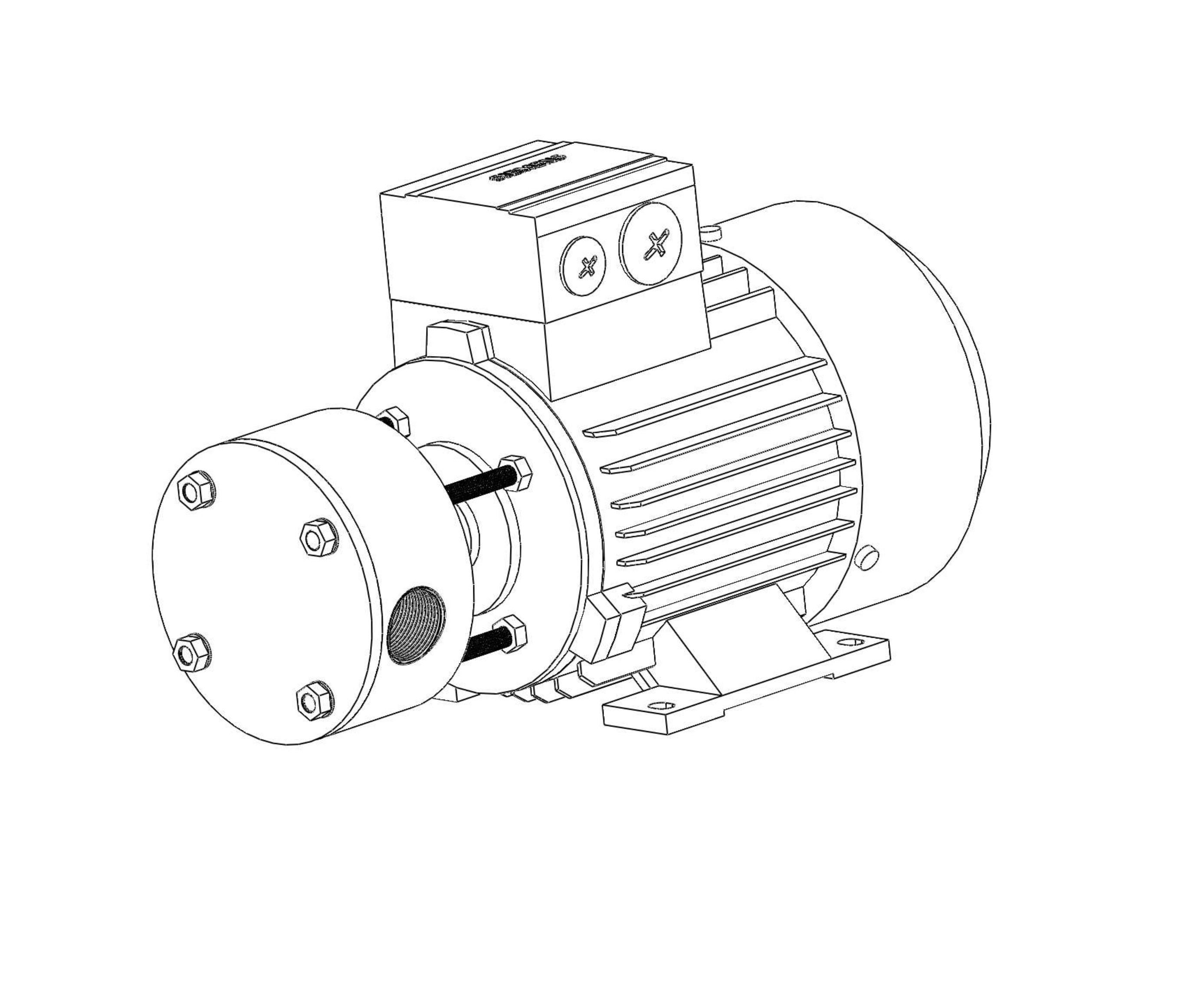

The compact positive displacement rotary vane MANUR pump of RKP series is oil-free, two-vane, single-stage, self-priming (does not require pre- filling of the housing and suction pipe-dry suction) up to 3.5 m (it depends on the viscosity, density and flow rate of the liquid), relatively low mass and dimensions. It is used to transport various liquids: mechanical and insoluble impurities (max 0.2% by mass and 0.2 mm), ordinary, toxic, combustible, explosive, crystallizing, sticky mixtures, creams, resins, mixtures of liquids and gases etc. It allows constant flow. It is economical and high-efficient energy device with a flexible mono-block version (mono-block standard IEC electric motor/gear motor with one-piece shaft). The speed of the shaft and the flow of the pump are directly proportional. The overall degree of efficiency of the pump practically remains constant over the entire working range of pressures.

In our innovative RKP design, the vanes made of high quality POM thermoplastic have good antifriction and other properties that ensure good sealing and exploitation of the volume and good rotor technology, whereby a very large flow of fluid can be achieved taking into account the overall dimensions. The pump housing has inner radii with distant centers, which makes it unnecessary to use springs or fluid pressure under the vanes, and the vanes are radially unloaded, which minimizes their wear, fluid acceleration and noise level. Fluid compression and swirling were eliminated and current pulsation was avoided. In idle mode, the pump closes almost completely, preventing backflow, siphoning and slipping. Optimal static sealing of the cover is achieved with an FPM O-ring.

Parts of MANUR pumps are made of stainless steel AISI 304. High-tech processing increases the reliability and efficiency of the pump. The design of the increased inlet port practically eliminates cavitation, improves pump pressure and extends pump life. Seal with composite PTFE lip type of FREUDENBERG SIMRIT have increased the service life of the pumps several times and has a high degree of sealing reliability as a mechanical seal. These pumps can be used in both open and closed systems, humid and explosive environment. They can be mounted vertically, horizontally, individually, in series/parallel, as a booster pump, stationary/mobile unit.

The pumps fully meet the spectrum of hygienic and industrial requirements for transporting liquids in the food, pharmaceutical, cosmetic, chemical industry, energy, petrochemical, shipbuilding, agriculture, drinking and technical water etc., without breaking, damaging, spoiling, delaminating, foaming, mixing solutions and aroma changes. They are also used for dosing, filling, mixing, spraying, circulation and as laboratory pumps. The pumps are also designed as mixers for continuous/serial mixing of fluids.

COMPARATIVE ADVANTAGES

- Available in various flow configurations, modularity, certificate EN ISO 9001

- Minimum dimensions and masses, mounted on 50/60 Hz electric motors/gear motors B3/B14 IEC, F, IP55, ATEX/IECEx

- Easy visual inspection, operation without maintenance, long service life

- Quiet and smooth operation, low vibration and pulsation, gentle continuous transport, control range between 25% and 100%

- Constant flow, good repeatability, have a higher degree of efficiency and suction lift than the centrifugal, gear and screw pumps

- Flow direction of the transported liquid can be changed by changing the direction of rotation (bi-directional rotation)

- High pump efficiency and reliability throughout the service life, 20-30% lower energy costs

- Connecting directly to the electric motor/gear motor, saving space

- It is not necessary to service the pump in the production line and the pipeline, they are cleaned and sterilized by CIP processes.